No.4,Second Industrial Zone, Hetian, Houjie Town, Dongguan City, GD, China. 523945 +86-18903039576 [email protected]

ESD, or Electrostatic Discharge, happens when electricity jumps suddenly between two charged objects. Most often, this occurs through everyday actions like rubbing materials together, touching surfaces, or pulling them apart something that happens constantly on factory floors. When these imbalanced electrical charges get a chance to escape, they can wreak havoc on delicate electronics being assembled in production facilities and cleanrooms alike. According to research from various sources, around 25% of failed components during manufacturing run into trouble because of ESD problems. These numbers tell us why manufacturers need to spot areas where static builds up and take steps to control it before it causes expensive downtime and product losses.

ESD can really mess up electronics, causing problems that last days or even years after they happen. When things go wrong right away, we usually see devices stop working completely or products fail during manufacturing and testing stages. This kind of stuff causes major headaches for factories when production lines have to stop and money gets wasted fixing or throwing away damaged goods. What's worse is what happens later on. Sometimes ESD damage doesn't show up immediately but instead creates hidden flaws that make products break down faster than expected. Industry numbers tell us that about one third of all component failures over time actually come from static electricity issues. That's why companies need good protection strategies from day one of production through to when customers finally use the product. Getting this right means better quality control and fewer headaches down the road for everyone involved.

Hidden flaws in electronic components represent a major problem because they usually go undetected until after the device starts running, but these issues frequently lead to system failures down the road. Most of these problems come from electrostatic discharge (ESD) events during manufacturing or handling, which damage sensitive parts including microprocessors and memory chips. What makes this so frustrating is how random these failures appear. For companies, dealing with warranty claims and recalls costs serious money while customers face unexpected breakdowns when they least expect them. Some studies put global losses at around $4 billion each year from just these kinds of ESD related issues, which really highlights why proper prevention measures matter so much. Standards like ANSI/ESD S20.20 offer practical steps for managing static electricity risks throughout production facilities. Following these protocols helps factories avoid those costly surprises and keeps their products working properly for longer periods.

Antistatic fabrics work by adding conductive fibers to their makeup, which helps get rid of static charges. The conductive threads let electricity escape instead of building up, so there's less chance of getting those pesky electrostatic discharge problems. For places where electronics are made, it makes sense to go with certified antistatic stuff because ESD can really mess up sensitive gear and actually lower how good the final products turn out. Studies over time have found that these special fabrics protect tiny parts from getting damaged by static, which means better performance and longer life for electronic devices in general.

Static control coveralls come with special design elements that help get rid of static electricity buildup. The main things that stand out are the extra strong seams and fabric that lets air through but doesn't let static gather. Workers find these suits comfortable enough to wear all day long since they can bend and stretch naturally without feeling restricted. When it comes down to actual performance, how well these coveralls prevent electrostatic discharge really depends on those design details. People who work in places where even small sparks matter tell us that finding the right mix between staying protected from static and being able to do the job comfortably makes all the difference. That's why these specialized garments have become so essential for anyone working around sensitive electronic equipment or flammable materials.

Antistatic coveralls come in two main varieties reusable and disposable each with pros and cons depending on what workers need. The reusable ones save money over time since they last longer, even though buying them upfront costs more initially. On the flip side, disposable coveralls tend to be easier to handle and generally better for the environment in some ways, although companies end up spending more in the long run because they need to replace these constantly. Different jobs call for different solutions really. Reusable gear works best where people wear them day after day in cleanrooms or manufacturing settings. But for one off jobs or temporary work sites, disposables make sense as they eliminate cleaning hassles. According to several safety professionals consulted recently, neither option is universally superior. What matters most is matching the right kind of protection to actual working conditions and budget constraints across different facilities.

Getting proper grounding right matters a lot when it comes to stopping electrostatic discharge or ESD, which can wreck havoc on sensitive electronics across various industries. Grounding setups typically involve things like wrist straps, special shoes designed to prevent static buildup, and certain types of flooring material that help channel away static electricity before it causes problems. All these pieces work together to create what most companies consider essential protection against ESD risks. Take manufacturing plants for example those that invested heavily in good grounding practices report seeing far fewer issues related to static shocks damaging their gear. Beyond just protecting expensive machinery though, getting this right actually saves time and money too since there's less downtime when equipment doesn't get fried by unexpected static discharges during normal operations.

Keeping humidity at just the right level really matters when it comes to managing static electricity problems. When the air isn't too dry or too moist, there's less chance of those annoying static shocks building up, which makes Electrostatic Discharge (ESD) control much easier to manage. Another good approach involves using ionization methods that basically cancel out static charges as they form, providing ongoing protection against sudden discharges. Many manufacturing plants have installed these ionization systems and seen noticeable improvements in their ESD control efforts. Companies that invest in proper humidity control equipment along with ionizers tend to protect their expensive electronic gear better, cutting down on damage from unexpected static bursts that can ruin delicate components.

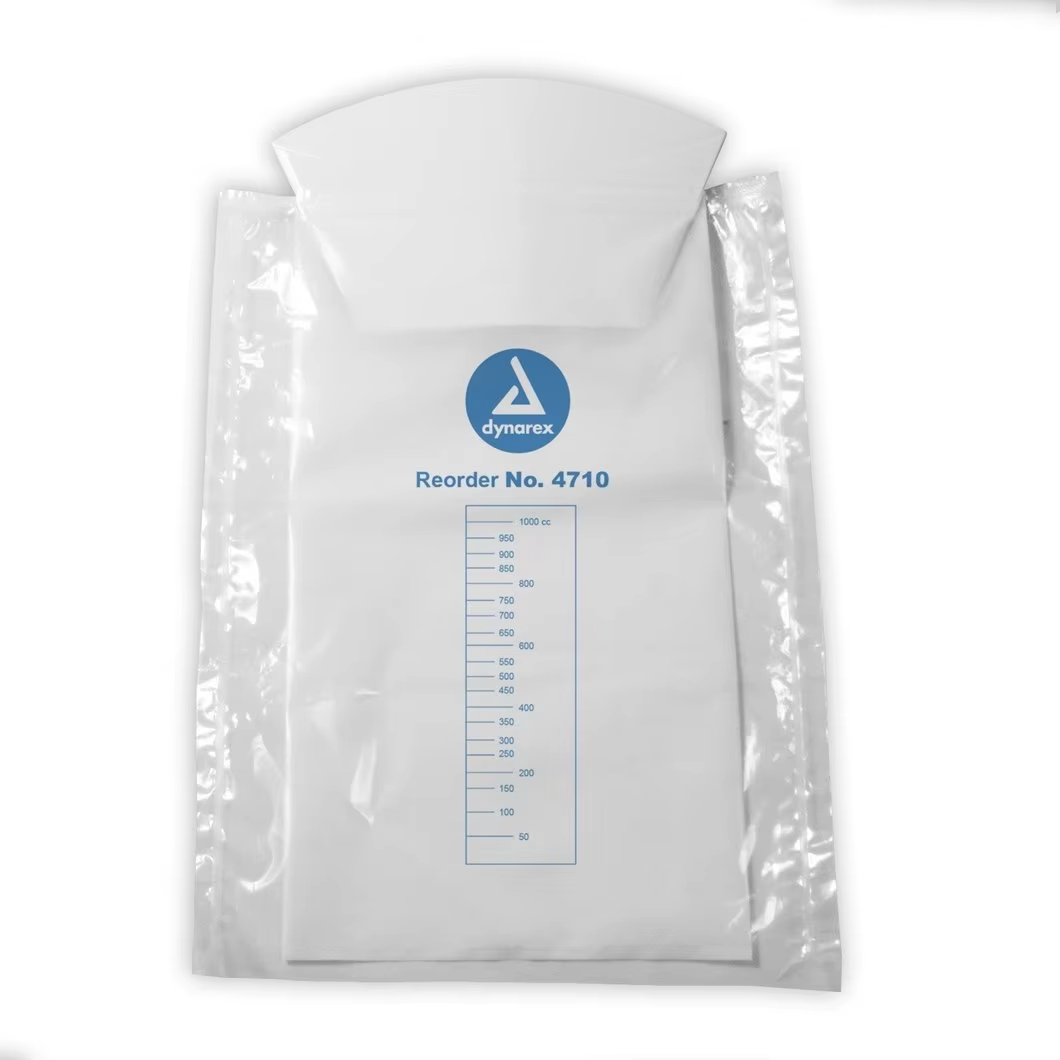

The right complementary ESD equipment makes all the difference when it comes to protecting against electrostatic discharge. Items like anti-static gloves, conductive mats, and specialized packaging work alongside coveralls to create better protection. These gloves and mats are made specifically to handle static electricity, which is why they should be part of any serious ESD protection plan. When transporting delicate electronic parts, ESD safe packaging becomes absolutely essential. The materials used in this packaging stop static from building up during shipping or handling. All these different pieces fit together like puzzle parts to create solid defense against ESD events. Without them, expensive equipment gets damaged, production slows down, and companies end up spending money fixing problems that could have been prevented with proper protection measures in place.

Knowing how conductive and dissipative textiles differ matters a lot when picking out good antistatic workwear for industrial settings. Conductive materials basically let electric current pass through their fibers, creating pathways for static charges to escape quickly. Dissipative fabrics work differently they actually slow down electrical flow instead of letting it go all at once, which helps avoid those sudden shocks we all hate. Both kinds show up in antistatic clothing, but what works best really depends on what kind of environment workers are dealing with day to day. Standards organizations like ASTM and IEC have established rules about how conductive different materials need to be for various applications to keep people safe from ESD dangers. When labs tested these fabrics side by side, they found conductive options tend to get rid of static faster, which makes them particularly useful in places where even small amounts of ESD might damage sensitive electronics during manufacturing processes.

Worker comfort matters just as much as durability when it comes to getting good results from staff working in dangerous conditions. When employees have work clothes that fit properly and don't trap heat, they tend to be happier at their jobs and actually remember to put on those safety items day after day. Nobody wants to wear something scratchy all morning while handling sensitive components. Speaking of which, durability becomes really critical in places like electronics factories. The uniforms there get washed constantly and take a beating during normal operations, yet still need to maintain proper ESD protection properties. Many factory managers report better attendance rates and fewer accidents once they switched to gear that workers actually wanted to wear. At the end of the day, making sure protective clothing works well for both comfort and long term use keeps production running smoothly without putting people at risk.

For antistatic coveralls to work well, they need to be part of a broader ESD safety plan. The plan must cover proper training for staff members too, along with periodic checks to make sure everyone follows the rules. Companies that do this right tend to update their safety guidelines on a regular basis, making sure coveralls fit with other protective equipment like ESD safe packaging materials and conductive gloves. Look at factories where ESD compliance works best – what makes them succeed? They combine good quality safety clothing with strict procedure following across the board. These businesses report fewer incidents because they treat static control as something ongoing rather than just buying gear once. The key takeaway? Regularly review how coveralls fit into daily operations and don't forget those simple but critical steps in between.

Workplaces looking to handle electrostatic discharge (ESD) risks properly need to follow the ANSI/ESD S20.20 standards. These standards give detailed instructions on setting up effective ESD control programs that protect not just the equipment but also keep employees safe from potential hazards. When it comes to getting ESD-safe clothing certified according to these standards, there's quite a bit involved. The process includes various tests to check if the clothing actually works against static electricity problems. Tests usually look at how well materials resist electricity and how quickly they lose any built-up charges. Getting this certification matters for everyone involved really. Manufacturers know their products meet important industry rules, while customers get something they can trust won't fail when needed most. Take certified ESD apparel for example it helps cut down on equipment breakdowns which saves money for companies operating in sectors where even small mistakes cost big bucks, think electronics manufacturing or pharmaceutical labs.

The EN 61340-5-1 standard has become essential for ESD safety across many parts of Europe, especially in places where electronics manufacturing happens regularly. What this standard does basically is lay out all sorts of procedures and practices to manage static electricity properly. It covers pretty much everything needed - how buildings should be designed, proper ways to ground people working there, even down to making sure machines don't accumulate dangerous charges. Companies that stick to these rules tend to put in place things like special floors that conduct electricity away and clothing made to prevent static buildup. These measures create what amounts to a buffer zone between workers and delicate electronic components. When businesses start following these standards seriously, operations tend to run smoother overall. Take one big German electronics manufacturer as an example. After implementing EN 61340-5-1 requirements, they noticed their equipment lasted longer and their production runs were much more consistent from day to day.

Regular testing plays a key role in maintaining ESD compliance so that anti-static clothing continues working properly over time. Testing typically covers several aspects including measuring surface resistivity, checking how well clothes can get rid of static electricity, and looking at environmental conditions that affect ESD protection levels. Most standards set out when these tests should happen regularly, usually somewhere between once a month and once every three months depending on what industry someone works in and how big the risks are. Experts in the field stress that ongoing checks matter because factories and the materials used there tend to change over time. When companies bring in new fabrics or equipment for instance, they may need to adjust their testing methods just to make sure everything still works against ESD problems.